Table of contents

If you work in an industry that involves hazardous activities or environments, such as construction, manufacturing, mining, or oil and gas, you may have heard of a cold work permit. But what exactly is it and why do you need it?

A cold work permit is a document that authorizes and regulates any work that does not involve open flames or heat sources but still carries a risk of injury or damage to people, property, or the environment. It is a way of ensuring that the work is done safely and in compliance with the Occupational Health and Safety Administration (OSHA).

According to the International Association of Oil & Gas Producers (IOGP), using a cold work permit system can help prevent accidents, injuries, and fatalities by 50% in the oil and gas industry. It can also help avoid costly damages, delays, and legal liabilities.

This blog post will teach you cold work permits and how to create a safe and compliant environment for yourself and your co-workers.

What Jobs Require a Cold Work Permit

Not all job tasks require a cold work permit. The criteria for determining if a job task requires cold work permits may vary depending on the workplace and industry policies and procedures.

Some examples of such activities are:

- Energized electrical work

- Movement of heavy equipment within a plant or a location

- Working from heights

- Confined space cold works

- Jobs involving toxic substances

- Jobs involving radiation sources

- Underwater cold works

- Excavation activities

- Dismantling or maintenance of safety-critical equipment

- Working in places where dangerous machinery may be operated remotely

- Dismantling or maintenance of machinery/ equipment that may contain residual energy

- Pressure testing

To help determine whether your specific task requires a cold work permit, try following these three guidelines:

The level of risk

If the job task involves a high or medium level of risk to people, property, or the environment, it may require a cold work permit. A low level of risk may not require a permit but still requires proper safety precautions and measures.

The type of work

If the job task involves any work that does not involve open flames or heat sources but still carries a risk of injury or damage to people, property, or the environment, it may require cold work permits.

The work environment

If the job task is performed in an environment that has potential hazards or risks that may affect the safety or performance of the work, it may require a cold work permit. Some examples of such environments are confined spaces, hazardous areas, or near sources of energy or hazards.

Steps for Obtaining and Issuing a Cold Work Permit

The process of obtaining and issuing cold work permits may vary depending on the workplace and industry policies and procedures. However, a general guideline for the steps involved is as follows:

1. Perform a Risk Assessment

Conduct a risk assessment for the task and the working environment to identify the hazards and the controls required. This may include inspecting the equipment, building, or area where the work will take place, checking the relevant safety data sheets (SDS), and consulting with other workers or experts.

2. Prepare the Work Area

Prepare the equipment, building, or area for the work, such as isolating, locking out, or de-energizing sources of energy or hazards, removing or covering combustible materials, providing adequate ventilation, or securing access points.

3. Complete Cold Work Permit

Fill out and authorize the cold work permit, specifying the work to be done, the location, the period, and the precautions to be taken. Cold work permits should include information such as:

- The name, contact details, and signature of the issuer and receiver of the permit

- The description, scope, and purpose of the work

- The date, time, and duration of the work

- The location, equipment, materials, tools, and personnel involved in the work

- The hazards and risks associated with the work and the surrounding area

- The controls and measures to be implemented to prevent or mitigate the hazards and risks

- The conditions, limitations, and restrictions to be followed during the work

- The emergency procedures and contacts in case of an incident or accident

4. Communicate

Communicate the permit to the workers involved and other relevant parties, such as supervisors, managers, or contractors. Ensure that everyone understands and agrees on the terms and conditions of the permit and their roles and responsibilities.

5. Maintain Documentation

Document and keep records of the cold work performed. This may include taking photos, videos, or notes of the work progress, the equipment used, the hazards encountered, or the incidents reported. The records should be stored securely and accessible for future reference or audits.

Roles and Responsibilities of the Issuer and the Receiver

The issuer and the receiver of the permit are the two main parties responsible for ensuring that the work is done safely and in compliance with occupational health and safety regulations and standards. They may be qualified personnel, competent workers, or authorized representatives, depending on the workplace and industry policies and procedures.

The Issuer

The issuer is the person who authorizes and approves the work to be done. Their duties and obligations include:

- Conducting a risk assessment for the task and the working environment to identify the hazards and the controls required

- Preparing the equipment, building, or area for the work, such as isolating, locking out, or de-energizing sources of energy or hazards

- Filling out and authorizing the cold work permit, specifying the work to be done, the location, the period, and the precautions to be taken

- Communicating the permit to the receiver and other relevant parties, such as supervisors, managers, or contractors

- Verifying that the receiver of the permit is competent, trained, and equipped to perform the work safely

- Inspecting and monitoring the work progress, equipment, area, and hazards periodically or as required

- Modifying, suspending, or canceling the cold work permit as necessary in case of changes in conditions, hazards, or risks

- Closing and signing off the permit upon completion of the work

The Receiver

The receiver of the permit is the person who performs or supervises the work to be done. Their duties and obligations include:

- Reading and understanding the cold work permit and its terms and conditions

- Agreeing to follow the precautions, measures, limitations, and restrictions specified in the permit

- Communicating with the issuer of the permit and other relevant parties, such as co-workers, supervisors, managers, or contractors

- Performing or supervising the work safely, competently, and efficiently

- Using appropriate personal protective equipment (PPE), tools, materials, and methods for the work

- Reporting any incidents, accidents, hazards, or issues that may arise during or after the work

- Returning or restoring the equipment, building, or area to its original or safe condition after completing the work

- Signing off and returning the work permit to the issuer upon completion

The issuer and receiver of cold work permits must have a mutual understanding and agreement on their roles and responsibilities. They must also communicate effectively and coordinate their actions to ensure that they are working towards a common goal: creating a safe and compliant work environment.

Importance of Following Cold Work Permit Procedures

Following conditions, precautions, and limitations specified in cold work permits is not only a legal requirement but also a moral obligation. It can help prevent potential consequences such as:

- Injuries, accidents, or fatalities to yourself or others

- Fires, explosions, or damages to property or environment

- Legal liabilities, fines, or penalties for non-compliance or negligence

Some examples of common violations or mistakes that can compromise the safety and effectiveness of a cold work permit system are:

- Failing to conduct a risk assessment before starting a task

- Failing to prepare equipment, building, or area for a task

- Failing to fill out or authorize a permit properly

- Failing to communicate or coordinate with other workers involved in a task

- Failing to follow precautions, measures, limitations, or restrictions specified in a permit

- Failing to document or keep records of a task

- Failing to report incidents, accidents, hazards, or issues that may arise during or after a task

As a worker involved in a cold work permit system, you have a responsibility to comply with occupational health and safety regulations and standards applicable to your workplace and industry. You also have a responsibility to protect yourself and others from harm.

Tips and Best Practices for Using a Cold Work Permit System

Using a cold work permit system can be challenging at times and time-consuming, but it can also be simplified and streamlined with some tips and best practices, such as:

- Using templates, checklists, or other digital tools to create, fill out, authorize, communicate, and store cold work permits. This can help save time, reduce errors, and improve consistency and quality.

- Improving communication and coordination among the workers involved in the cold work permit system, such as regular meetings, feedback sessions, or training programs. This can help enhance understanding, agreement, and collaboration.

- Enhancing the safety culture and awareness in the workplace, such as rewarding compliance, reporting incidents, or conducting audits. This can help foster a positive attitude, behavior, and mindset toward safety and compliance.

30+ Audit and inspection checklists free for download.

Difference between a Cold Work Permit and a Hot Work Permit

A hot work permit is another type of document that authorizes and regulates any work that will generate heat or sparks or create a flammable or explosive atmosphere. It is a way of ensuring that the work is done safely and in compliance with the Occupational Health and Safety Regulations and Standards.

Some examples of hot work activities that require a hot work permit are:

- Welding

- Cutting

- Grinding

- Drilling

- Riveting

- Using internal combustion engines

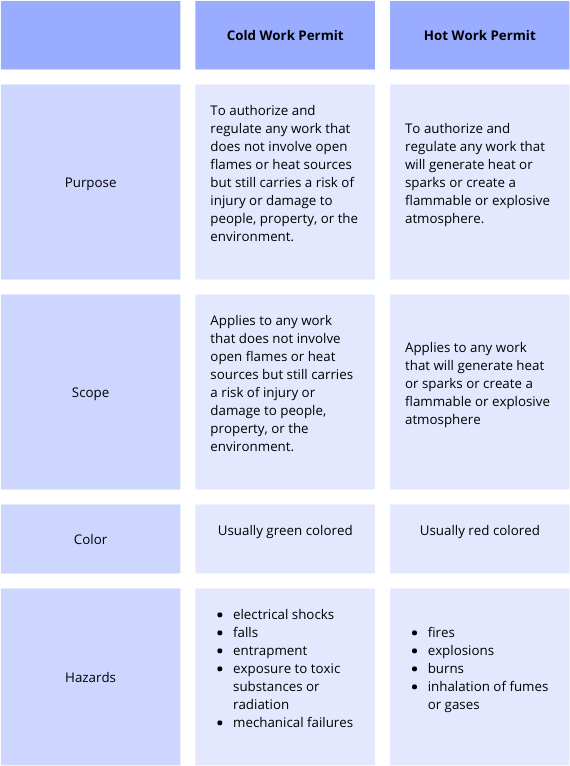

A cold work permit and a hot work permit have some differences in terms of their purpose, scope, color, and hazards involved. Here is a comparison table that summarizes them:

Some additional differences between a cold work permit and a hot work permit are:

- A cold work permit may require additional permits for specific types of work, such as confined space entry, excavation, or pressure testing. A hot work permit may not require additional permits but may require additional fire prevention and protection measures.

- A cold work permit may be valid for longer than 24 hours if the work is continuous and the conditions do not change. A hot work permit is usually valid for 24 hours or less and must be renewed if the work continues beyond the specified time period.

- A cold work permit may be issued by a competent worker who has the authority and knowledge to assess the risks and controls. A hot work permit must be issued by a qualified person who has the training and certification to perform or supervise hot work activities.

How to Improve Cold Work Permit Performance

Certainty Software helps you to easily create, fill out, authorize, communicate, and store cold work permits easily and efficiently. With Certainty Software, you can:

- Use templates, checklists, or digital tools to simplify and streamline the cold work permit process

- Improve communication and coordination among the workers involved in the cold work permit system

- Enhance the safety culture and awareness in the workplace

- Access real-time data and analytics on your cold work permit performance

- Comply with occupational health and safety regulations and standards

Certainty Software is not only for cold work permits but also for hot work permits and other types of permits to work systems. It is a versatile and flexible solution that can adapt to your specific workplace and industry needs. If you’d like to learn more about how Certainty can help with your cold work permits and other safety management needs, don’t hesitate to book a quick demo.

You may also be interested in: