Table of contents

Food safety is a crucial aspect of the food industry, as it affects the health and well-being of consumers, as well as the reputation and profitability of businesses. However, ensuring food safety is not an easy task. That’s because it involves complying with complex and dynamic regulations and standards, as well as managing various risks and hazards throughout the food supply chain. This is why obtaining businesses are enticed to obtain internationally recognized certifications. Doing so means they can demonstrate their commitment and competence in food safety management.

One of the most prominent food safety management systems (FSMS) is FSSC 22000, which stands for Food Safety System Certification 22000. FSSC 22000 is a robust FSMS that is widely accepted and recognized by global regulatory bodies and industry stakeholders. In this blog post, we will explain what FSSC 22000 is, how it was developed, what its key components are, what benefits it offers to businesses in the food industry, and how to obtain and maintain FSSC 22000 certification.

What is FSSC 22000?

FSSC 22000 is a FSMS that provides a framework for managing food safety risks and ensuring compliance with relevant regulations and standards. It is based on the international standard ISO 22000, which specifies the requirements for a FSMS, as well as other technical specifications for prerequisite programs (PRPs), which are the basic conditions and activities necessary to maintain a hygienic environment for food production. FSSC 22000 also incorporates the plan-do-check-act (PDCA) cycle, which is a systematic approach to achieving continuous improvement of the FSMS.

FSSC 22000 is globally recognized and accepted by various regulatory authorities and industry organizations. Some of which include the Global Food Safety Initiative (GFSI), which benchmarks FSMS against a set of criteria to ensure effectiveness and consistency. It is also compatible with other quality management systems standards, such as ISO 9001 (quality management) and ISO 14001 (environmental management). These enabled businesses to integrate their management systems and achieve greater efficiency and performance.

The History and Development of FSSC 22000

FSSC 22000 was developed by the Foundation for Food Safety Certification, a non-profit organization based in the Netherlands, in collaboration with various stakeholders from the food industry, such as manufacturers, retailers, certification bodies, accreditation bodies, and experts. The Foundation for Food Safety Certification was established in 2004 to create a harmonized FSMS that would meet the needs and expectations of the global food market.

Let’s take a look at the development of FSSC 22000 throughout the years.

2009:

The first version of FSSC 22000 was published. It was based on ISO 22000:2005 and PAS 220:2008 (a technical specification for PRPs for food manufacturers).

2011:

FSSC 22000 was recognized by GFSI as equivalent to other GFSI-benchmarked schemes.

2013:

FSSC 22000 was revised to include ISO/TS 22002-1:2009 (a technical specification for PRPs for food manufacturers) instead of PAS 220:2008.

2017:

FSSC 22000 was updated to align with ISO 22000:2018 (the latest version of ISO 22000) and ISO/TS 22002-1:2009. In addition, it expanded its scope to cover other sectors of the food industry such as catering, retail, transport and storage, feed production, animal production, fishing vessels, etc., by incorporating other technical specifications for PRPs relevant to each sector.

2020 (current version):

The current version of FSSC 22000 is version 5.1 and includes some minor changes and clarifications to version 5.0, which was published in June 2019. Version 5.1 also introduces some new requirements for certification bodies and auditors to ensure consistency and integrity of the certification process.

Key Components of FSSC 22000 Certification

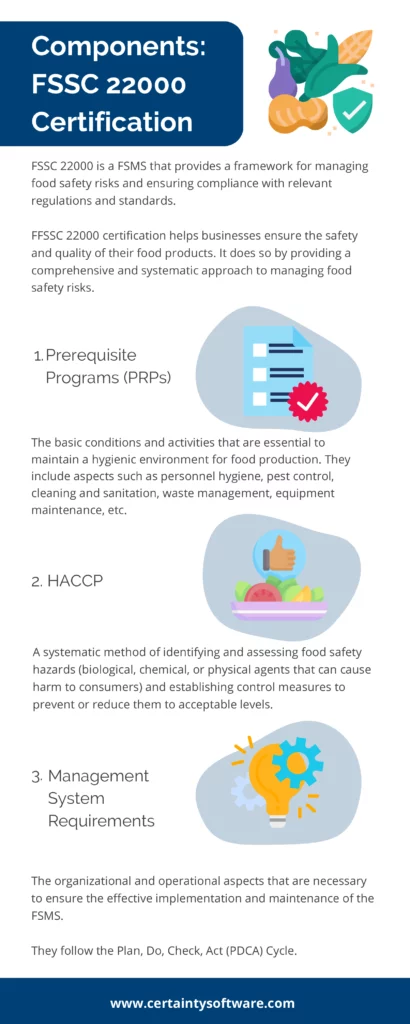

FSSC 22000 certification consists of three main components: PRPs, Hazard Analysis and Critical Control Points (HACCP), and management system requirements.

Prerequisite Programs (PRPs) are the basic conditions and activities that are essential to maintain a hygienic environment for food production. They include aspects such as personnel hygiene, pest control, cleaning and sanitation, waste management, equipment maintenance, etc. PRPs are based on the technical specifications for each sector of the food industry, such as ISO/TS 22002-1 for food manufacturers, ISO/TS 22002-4 for food packaging manufacturers, etc.

HACCP is a systematic method of identifying and assessing food safety hazards (biological, chemical, or physical agents that can cause harm to consumers) and establishing control measures to prevent or reduce them to acceptable levels. HACCP involves seven principles:

- conducting a hazard analysis,

- determining the critical control points (CCPs);

- establishing critical limits, monitoring CCPs;

- establishing corrective actions;

- verifying the effectiveness of the HACCP system;

- documenting and recording the HACCP system.

Management system requirements are the organizational and operational aspects that are necessary to ensure the effective implementation and maintenance of the FSMS. They are based on ISO 22000, which specifies the requirements for a FSMS, such as:

- leadership and commitment;

- policy and objectives;

- planning, resources;

- communication;

- operational control;

- performance evaluation;

- improvement.

Management system requirements also follow the PDCA cycle. This cycle consists of four phases:

- plan (establish objectives and processes);

- do (implement processes);

- check (monitor and measure results);

- act (take actions to improve).

Benefits of FSSC 22000 Certification

Certification offers various benefits to businesses in the food industry, such as:

Enhanced Food Safety and Risk Management

FSSC 22000 certification helps businesses ensure the safety and quality of their food products. It does so by providing a comprehensive and systematic approach to managing food safety risks. By implementing PRPs, HACCP, and management system requirements, businesses can identify and control potential hazards throughout the food supply chain. Certification also enables businesses to adopt preventive measures and corrective actions to prevent or minimize the occurrence of food safety incidents. Furthermore, becoming certified fosters a safety culture of continuous improvement by encouraging regular monitoring, evaluation, and review of the FSMS performance and effectiveness.

Compliance with Regulatory Requirements

FSSC 22000 certified organizations are more capable of complying with relevant food safety regulations and standards in their markets. For instance, this certification is aligned with the Codex Alimentarius, which is a collection of internationally recognized guidelines and standards for food safety and quality. It is also recognized by various regulatory authorities and industry organizations around the world. One example is GFSI, which benchmarks FSMS against a set of criteria to ensure their effectiveness and consistency. By obtaining FSSC 22000 certification, businesses can demonstrate their compliance to customers, regulatory authorities, and business partners.

Marketability and Customer Confidence

By becoming certified, businesses enhance their reputation and credibility in the food industry. This is done by showing their commitment and competence in food safety and sustainability. Certification can also increase customer confidence and satisfaction by assuring them that the food products they consume are safe and of high quality. Moreover, FSSC 22000 certification can give businesses a competitive edge in the global food market by enabling them to access new markets and customers that require or prefer certified suppliers.

How to Obtain FSSC 22000 Certification

Preparing for Certification

The first step in obtaining FSSC 22000 certification is to prepare for it by establishing and implementing an FSMS that meets the requirements of FSSC 22000. This involves:

- Conducting a gap analysis to assess the current state of the FSMS and identify any gaps or areas for improvement.

- Establishing PRPs based on the technical specifications for each sector of the food industry.

- Implementing HACCP based on the seven principles of hazard analysis and control.

- Developing a robust management system based on ISO 22000 requirements and the PDCA cycle.

30+ Audit and inspection checklists free for download.

Engaging Certification Bodies

The next step in obtaining FSSC 22000 certification is to engage with an accredited certification body that can conduct an assessment and audit of the FSMS. This involves:

- Selecting a certification body that is authorized by the Foundation for Food Safety Certification and accredited by a member of the International Accreditation Forum (IAF).

- Applying for certification with the chosen certification body and providing relevant information and documentation about the FSMS.

- Undergoing an assessment stage, which consists of a document review and an on-site visit by the certification body. This is to verify the compliance of the FSMS with FSSC 22000 requirements.

- Undergoing an audit stage, which consists of an initial certification audit (a two-stage audit that evaluates the implementation and effectiveness of the FSMS) and subsequent surveillance audits (periodic audits that monitor the continued compliance of the FSMS with FSSC 22000 requirements).

Maintaining Certification and Continuous Improvement

The final step in obtaining FSSC 22000 certification is to maintain it by ensuring compliance with FSSC 22000 requirements. This involves:

- Maintaining PRPs, HACCP, and management system requirements by following the established procedures and processes.

- Conducting ongoing monitoring and measurement of the FSMS performance and results, such as food safety indicators, customer feedback, audit findings, etc.

- Conducting internal audits and management reviews to evaluate the effectiveness and suitability of the FSMS and identify any opportunities for improvement.

- Taking corrective actions and preventive actions to address any nonconformities or potential nonconformities of the FSMS and prevent their recurrence or occurrence.

- Staying updated with any changes or updates to FSSC 22000 requirements and implementing them accordingly.

A Solution for FSSC 22000 Internal Audits and Inspections

One of the key requirements of FSSC 22000 is to conduct internal audits and inspections. Doing so will help to verify the compliance and effectiveness of the FSMS and identify any areas for improvement. However, managing internal audits and inspections can be challenging and time-consuming, especially for enterprise organizations with multiple sites, departments, and processes. That’s why many businesses use Certainty, a safety audit and inspection solution that simplifies and streamlines the management of internal audits and inspections.

Certainty allows your business to:

- Create and customize audit and inspection checklists based on FSSC 22000 requirements and best practices.

- Schedule and assign audit and inspection tasks across your organization.

- Conduct audits and inspections using mobile devices, even offline, and capture data, photos, signatures, etc.

- Analyze your audit and inspection data in real-time using dashboards, reports, charts, etc.

- Identify and track nonconformities, corrective actions, preventive actions, etc.

- Share your audit and inspection results and feedback with relevant stakeholders.

If you’d like to learn more about how Certainty can support your FSSC goals, schedule a quick call with us.

you might also be interested in: