Despite improved safety standards and oversight, workplace risks remain. According to OSHA data, more than 100 workers died on the job every week in 2019 — and the construction industry accounted for 20 percent of these fatalities. As a result, construction safety observations are a critical component in reducing risk and increasing worker safety, in turn improving business performance by keeping staff healthy, safe and productive.

Here’s what you need to know about effectively implementing construction safety observations.

What are Construction Safety Observations?

Safety observations are designed to pinpoint potential problem areas in your workplace. These include everything from near misses to falling and tripping hazards, unsafe machinery, or issues with personal protective equipment (PPE) — such as hard hats, goggles, or coveralls — being underutilized or misused.

These observations provide the insight companies need to continually improve business safety practices, in turn reducing the risk of serious injury or death. Observations also play a critical role in compliance — companies must demonstrate due diligence in workplace safety practices to ensure staff is not unduly exposed to risk.

What is a Good Construction Safety Observation?

A good safety observation is one that pinpoints a potential problem and helps companies identify a strategy for remediation. Both components are critical: If safety teams observe and report problems but management makes no effort to resolve them until an incident occurs, the observations are wasted time.

Similarly, remediation strategies that lack context can limit the efficacy of health and safety observations. For example, if a specific piece of machinery is periodically causing injury, simply adjusting PPE requirements may temporarily solve the problem without addressing the root cause, which may be tied to a specific fault in the device or require a complete replacement of the machine. By prematurely “fixing” the issue without fully investigating the problem, businesses may avoid small issues but set the stage for serious injuries or death.

How Do Observations Help Your Business?

Observations help your business by taking a proactive approach to identify potential areas of risk — before staff is injured or machinery is damaged. By regularly collecting observational data about current operations and their impact on overall safety, companies can develop strategies to actively mitigate risk.

Consider an observation of a cluttered workstation that creates an unsafe environment. By identifying the issue and speaking with staff to determine the root cause, businesses can take steps to remove unnecessary items and reconfigure the workstation to both improve performance and reduce risk. While this requires both time and effort, it’s preferable to the much more substantial costs associated with regulatory fines and potential lawsuits if staff is seriously injured at work due to a known issue.

30+ Audit and inspection checklists free for download.

What Should be Included in a Construction Safety Observation Report?

Good construction safety observations include six key components:

Designated observers

Specific staff members should be assigned the role of safety officers’ observations to ensure consistency across safety data collection and reporting.

Scheduled times

Companies must schedule regular time for observations and ensure these observations are consistently carried out to ensure observations address key issues.

In-depth observations

Observation reports must include in-depth descriptions of symptoms, problems, and root causes to help companies create effective safety strategies across diverse worksites.

Employee conversations

Along with physical observations, it’s critical to connect with multiple team members and ask them about their work area safety experiences to provide context around potential problems.

Comprehensive checklists

Comprehensive safety checklists and templates help staff quickly pinpoint potential issues across complex work environments and define clear corrective actions.

Robust reporting

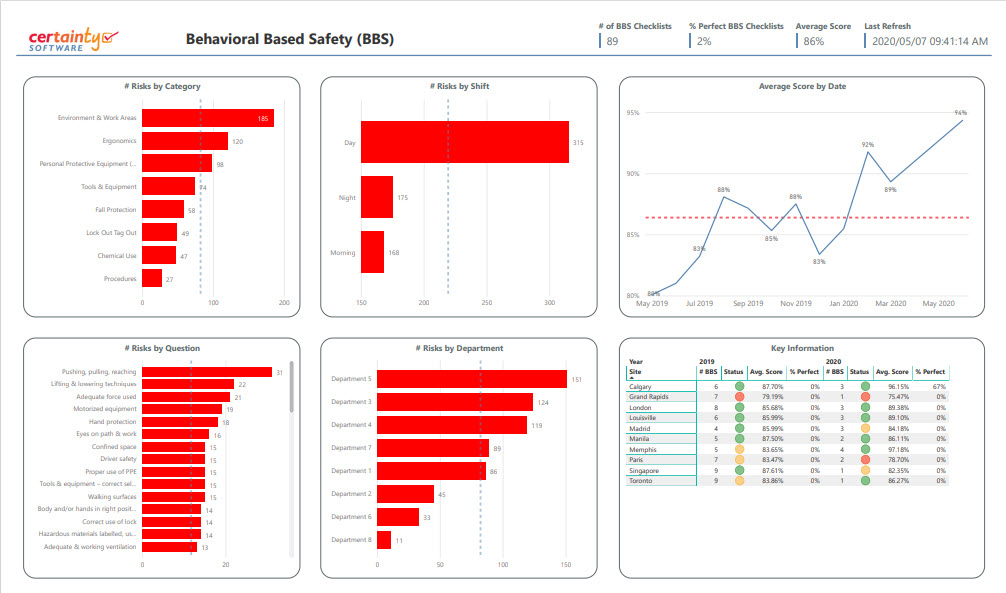

In-depth safety audit software allows staff to ensure construction observation safety reports are complete, accurate, and can be easily shared with stakeholders.

Construction safety observation reports are critical to boosting productivity, reducing total risk, and ensuring regulatory compliance. Ready to streamline your safety observations and develop better safety procedures?

You may also be interested in:

Case Study: How Vaughn Industries streamlined their safety observations with Certainty