According to one study, businesses that implemented the ISO 9000-based quality standards found an 18% increase in client satisfaction and a 15% cost reduction. ISO 9001 is an internationally recognized Quality Management System (QMS) criteria program. This program guides businesses of any size to maintain or find improvements in their quality management system and processes. The ISO approach […]

What Are Quality Assurance Inspections And Why They Matter

While price and positive experiences remain the leading factors in brands’ abilities to keep customers satisfied, quality also plays a critical role. According to research firm PWC, 52 percent of U.S. consumers would consider switching from one brand to another based on product quality. The result? It’s critical for companies to create policies and processes that […]

ESG Score: What It Is And Why It Matters

Environmental, social, and governance (ESG) frameworks are a priority for organizations. According to the 2022 EY US CEO survey, 82 percent of chief executives see ESG “as a value driver to their business over the next few years,” as both stakeholders and customers look for evidence that companies are doing their part to reduce negative environmental […]

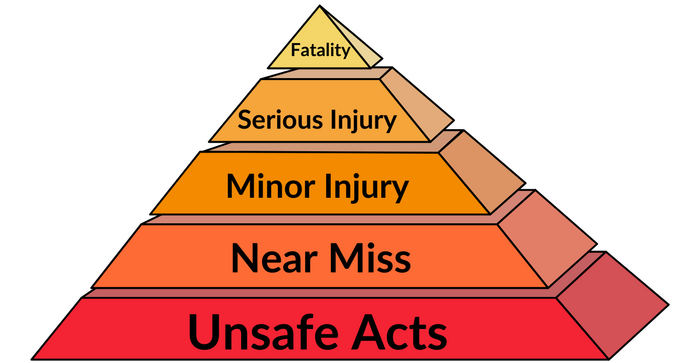

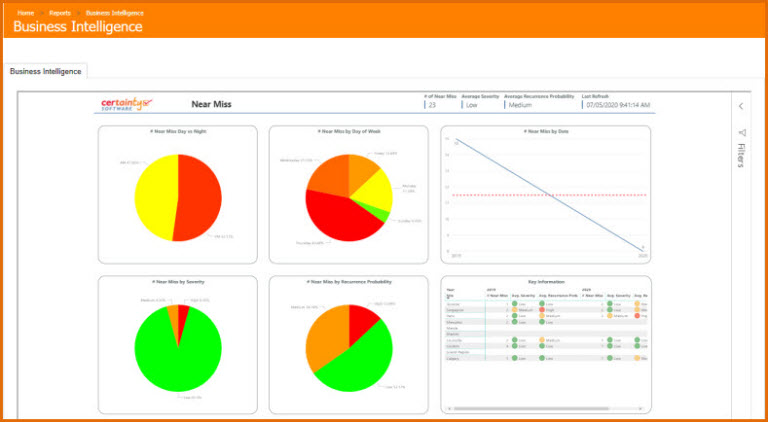

Near Miss Reporting: What it is and Why it’s Important

According to the U.S Department of Labor, there were 4,764 workplace fatalities in 2020. Transportation incidents, falls, slips, trips, contact with objects and equipment, and exposure to harmful substances were the leading causes of death. Near misses contribute significantly to workplace fatalities regardless of their minimal effects at the moment. For every 600 near misses, 30 […]

Keep it Seen, Keep it Safe: The Importance of Construction Safety Observations

Despite improved safety standards and oversight, workplace risks remain. According to OSHA data, more than 100 workers died on the job every week in 2019 — and the construction industry accounted for 20 percent of these fatalities. As a result, construction safety observations are a critical component in reducing risk and increasing worker safety, in […]

Seeing is Succeeding: Why Supply Chain Visibility Matters

Supply chain operations remain top of mind for companies across the globe. Airfreight warehouses and shipping ports are backlogged, and the cost of transporting goods has risen exponentially as pandemic pressures disrupted familiar supply chain routes even as customers made the move to online ordering that came with promises of free, fast delivery. Put simply, […]

The HACCP Plan: How it Can Help Reduce Food Safety Risk

Food safety is a top priority for organizations. As noted by the CDC, more than 48 million Americans get sick each year due to foodborne illness, and over 120,000 are hospitalized. The agency also points out that challenges around food safety will continue to evolve thanks to changes in food production processes, supply chain options, […]

ESG Investing: Benefits and Implications for Businesses

Sustainable businesses are now driving investment. As noted by Bloomberg, assets under management (AUM) tied to companies with superior environmental, social and governance (ESG) practices in place are on track to reach $53 trillion by 2025, which represents one-third of AUM worldwide. But what exactly are ESG and ESG Investing? Why does it matter to […]

Incident Reporting: A Key Component of an Effective Safety Management Program

No workplace is perfectly safe. Despite best efforts, incidents happen — machines may experience sudden failures or staff may unintentionally expose themselves or others to risk. Consider recent data from the U.S. Bureau of Labor Statistics (BLS), which found that private industry employers reported 2.7 million nonfatal workplace injuries and illnesses in 2020. While the […]

Kaizen for Continuous Improvement: How it Works

More efficient businesses are more profitable. If employees are not wasting time on redundant, cumbersome, or complex processes, they’re better able to perform their jobs and ensure production targets are met. The challenge? Creating efficient operations isn’t a one-and-done process. Instead, companies need a continuous improvement approach that prioritizes ongoing evaluation to drive sustained success. […]